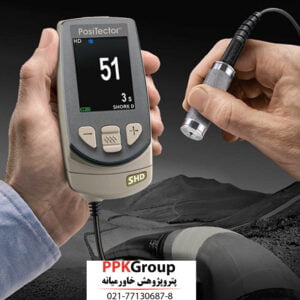

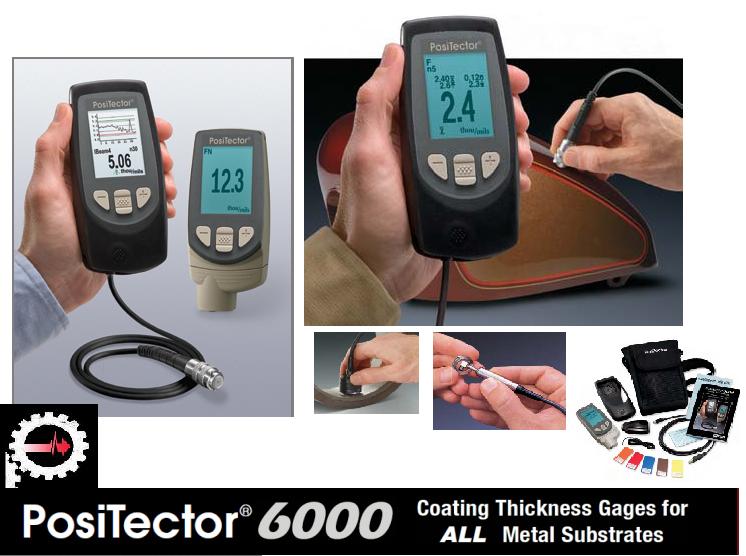

| | | | PosiTector 6000 Series for All Metal (Ferrous and Non Ferrous) Substrates | | | | Rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on both ferrous and non-ferrous metals, accurately and quickly.- Ideal for Measuring Paint, Powder Coating, Epoxy, Anodizing, Plating and More !

- Measure Coating thickness on both Ferrous and Non Ferrous Metals

- Ready to measure- no calibration adjustment required for most application

- Solvent, acid, oil, water and dust resistant

- Certificate of calibration showing traceability to NIST included

- Mils/Micros/mm switchable

- 2 Year Warranty

- Built-in temperature compensation ensures measurement accuracy

Powerfulness of Guage - Statistics mode continually displays/updates average, standard deviation, min/max thickness and number of readings while measuring

- HiLo alarm audibly and visibly alerts when measurements exceed user-specified limits

- FAST mode – faster measurement speed for quick inspection

- USB port for fast, simple connection to a PC and to supply continuous power. USB cable included

- Software updates via web keep your gage current

- Multiple measurement download/transfer options:

- USB mass storage – stored readings and graphs can be accessed using universal PC/ Mac web browsers or file explorers. No software required

- PosiTector.net – a free web-based application offering secure storage of thickness readings

- PosiSoft Software Compatible – Continue using the familiar legacy software you have used for years. Available as a free download.

- Every stored measurement is date and time stamped

- Extended cables available ( upto 75m/250ft ) for underwater or remote sensing.

| | |

|

|

| All guage come complete with precision plastic shims , protective rubber holster with belt clip , wrist strap,3AAA alkaline batteries , instructions , nylon carrying case with shoulder strap , protective lens shield , Long form certificate of calibration traceability to NIST , USB Cable , 2 year warranty ( Mechanical damages caused to the instrument and probe are not included under warranty ). |

| |

| Gage Selection: |

| |

|

| |

| |

| |

| |

| |

| Coating Thickness Gage for Concrete, Wood, Plastic and More |

| |

PosiTector 200 Series- Non-Destructively measures a wide variety of applications using proven ultrasound technology

- Measures Coating Thickness over Wood, Concrete , Plastics, Composites and more.

- Advanced models measure up to 3 individual layer thickness in a multi layer system

- Solvent ,acid, oil, water and dust resistant

- Continually displays averages, standard deviation, and number of readings

- Internal memory stores up to 10,000 readings in up to 1000 batches:

- Proven Non-destructive ultrasonic technique conforms to ASTM D6132 and ISO 2808 and SSPC PA9.

- Built in clock to date and time stamp each stored measurement.

- Certificate of calibration showing traceability to NIST included.

All gauge include probe, precision plastic shims , protective rubber holster with belt clip , couplant , 3AAA batteries , instructions , nylon carrying case with shoulder strap , certificate of calibration traceable to NIST . 2 year warranty ( Mechanical damages caused to the instrument and probe are not included under warranty ) | |

|

| |

| |

| |

| |

| |

| |

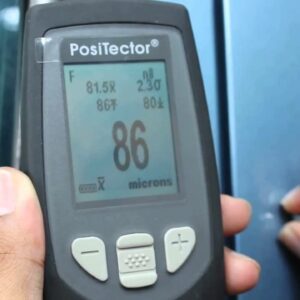

| PosiTest DFT Coating Thickness Gage for all Metals |

| | |

The PosiTest DFT coating thickness gage measures coatings on ALL metals.

Its ideal use for Automotive refinishers , resellers ,Dealerships & Coating Inspectors:

Two Models: Measures Non Magnetic coatings on Steel Measures both non-magnetic coatings on steel and non-conductive coatings on Aluminum , brass , etc . Automatically recognizes the substrate and take a measurement:

Gage Features: - Flip Display for right side up viewing in any position

- No calibration required

- Zero feature for rough and curved surfaces

- Handy RESET feature

- 2 year Warranty

- V-Groove in probe for positioning on cylindrical parts.

| |

| | |

| Posipen Measuring Coating Thickness |

| | |

PosiPen can be placed with pin-point accuracy on any location of the part to be measured which other Gages are not able to reach. | |

| | | PosiPen measures | Range | | - 5 to 500 microns (metric)

| | - Tolerance ±10% and 2.5 microns

| | | | | |

|

PosiTest PosiTest FM / GM – Magnetic pull-off thickness gage for the Non-destructive measurement of non-magnetic coatings (paint, enamel, plastic, galvanizing, metalizing, plating, etc.) on STEEL. |

| | |

| |

| PosiTector PC Powder Checker |

| |

Measures uncured powder coatings using non-contact ultrasonic technology to automatically calculate and display a predicted cured thickness. - Hand held , battery operated.

- Thickness results appear on both base unit and probe.

- Advanced new technology allows measurement on small tubes , odd shapes and moving parts:

- Wireless probe communicates with base unit up to 10m away.

- Continuous displays/updates basic statistics including min/max and average.

- USB mass storage of 1000 readings in up to 100 batches .

- USB port for fast and easy connection to a PC and to supply continuous power. No download software required. Gage generates formatted reports with measurement summaries and charts.

- Gage comes with with base unit and probe, protective rubber holster with belt loop and magnetic mount, probe fixture, 3 AAA batteries (base unit), 3 AA batteries (probe), instructions, instructional video, replacement probe screen, USB cable, carabiner and wrist strap, durable carrying case, two (2) year warranty. ( Mechanical damages caused to the instrument and probe are not included under warranty ).

Specification: Why measures uncured powder?

Coatings must be applied within certain minimum and maximum dry film thickness specifications. But waiting to measure coating thickness after curing can result in product waste and production delays. Accurate measurement at the time of application: - Eliminates over usage

- Improves quality

- Controls set-up

- Reduces waste

- Saves money.

| |

| |

|

|

| PosiTector Surface Profile Gage |

| |

The PosiTector SPG Surface Profile Gage measures and records peak to valley surface profile heights. Conforms to ASTM D4417-B, AS 3894.5-C (with optional 30° tip angle), U.S. Navy NSI 009-32, SANS 5772. - Fast measurement rate of over 50 readings per minute – ideal for quickly and accurately measuring surface profile over large surface areas

- 60º angle tungsten carbide Nozzle tip for long life and continuous accuracy – field replaceable

- 30º angle interchangeable probe tip available for special surface profile applications

- Continually displays/updates average, standard deviation, min/max thickness and number of surface profile readings

- USB port for fast, simple connection to a PC and to supply continuous power. USB cable included

- Selectable display languages

- Two (2) year warranty on body and probe. ( Mechanical damages caused to the instrument and probe are not included under warranty).

| |

| |

| |

| |

| PosiTector Inspection Kit: |

| |

PosiTector Inspection Kits contain a PosiTector gage body (Standard or Advanced) and 3 probes – coating thickness, environmental and surface profile, as well as, accessories in a convenient hard shell carrying case Kits come complete with a gage body (Standard or Advanced), coating thickness probe (user selected), environmental probe, surface profile probe, precision plastic shims, glass zero plate and metal shim, protective rubber holster with belt clip, wrist strap, 3 AAA alkaline batteries, 3 instruction manuals, hard shell case, protective lens shield, 3 Long Form Certificates of Calibration traceable to NIST, USB cable and 2 year warranty on gage body and probes. | |

| |

دستگاه جدید ضخامت سنج رنگ-پوشش با کابل جدا با سیستم آهنی و غیر آهنی ساخت آلمان

دستگاه جدید ضخامت سنج رنگ-پوشش با کابل جدا با سیستم آهنی و غیر آهنی ساخت آلمان